A DEMONSTRABLE DIFFERENCE

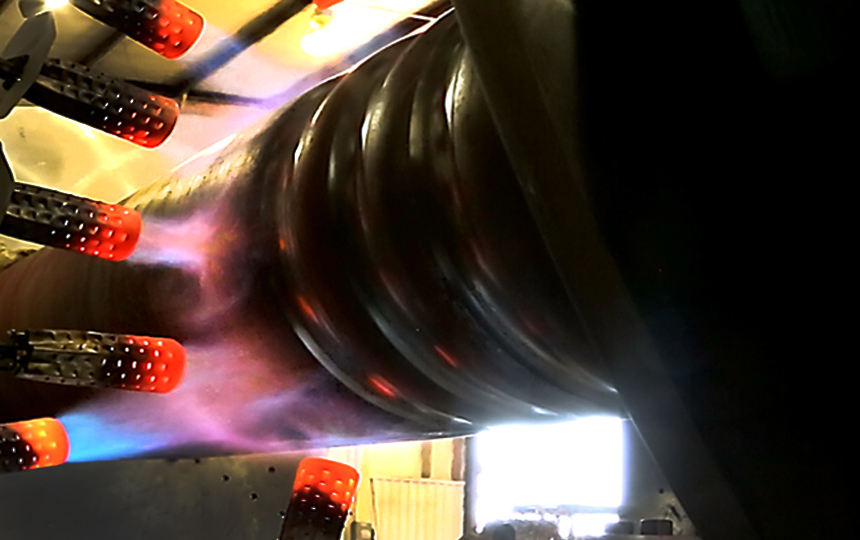

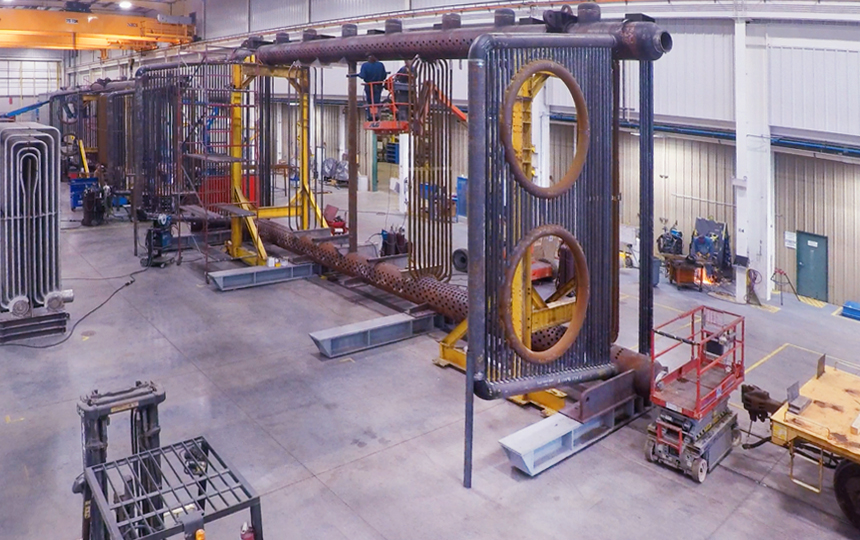

Victory Energy manufactures at two locations in Oklahoma ─ our headquarter operation in Collinsville, and in Cushing. Each operation is a state-of-the-art facility that features the latest technological advances in manufacturing. The goal is to deliver on our overriding mission promise ─ providing our customers with the best watertube and firetube boilers, burners, HRSG’s, heat transfer solutions and services.

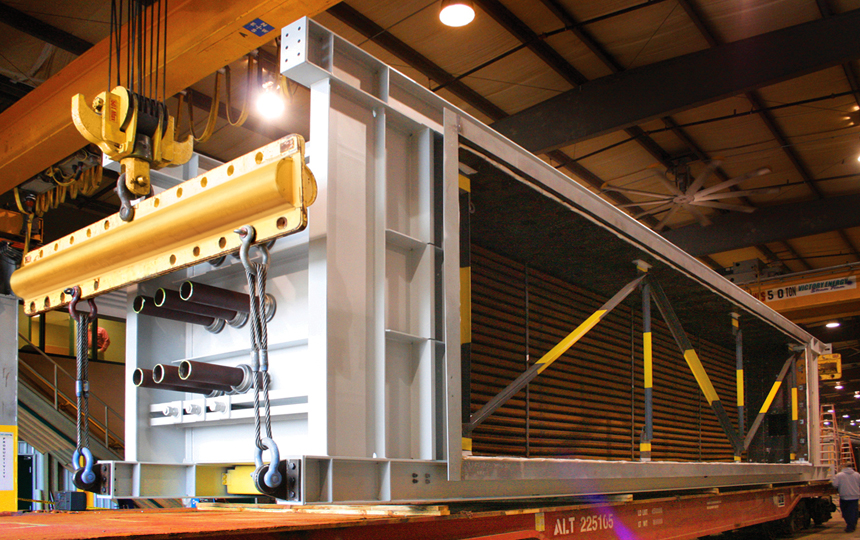

The company is totally focused on implementing lean principles across every aspect of the manufacturing process. It’s about eliminating waste, reducing lead times and delivering quality products. The result is reduced man hours across the plant with subsequent increases in productivity. The laser focus on being lean is allowing us to move toward a Pulse Line approach of moving boilers through the manufacturing plant in a defined time frame that sets the standard for delivery times in the industry.

We’ve gone to great lengths to define a quality control process that is distinctly owned by every employee that touches a boiler product on the shop floor. An Inspection and Test Plan document with detailed checklists accompanies each product throughout the manufacturing process. Products are subjected to hold points, over 100 in total, to ensure quality integrity. We’re totally transparent and open to customers being involved as their boilers are being manufactured.

In 2016, a 75,000 square foot expansion was completed to enhance our manufacturing footprint in direct response to what the market was asking of us in larger boilers and HRSG products. A new CNC core drilling machine has reduced the drilling time of core vessels from several weeks to one to two days.

Every action that we take in our manufacturing operations is aimed at delivering a superior quality product in the shortest timeframe.

QUICK LINKS